BayMeters

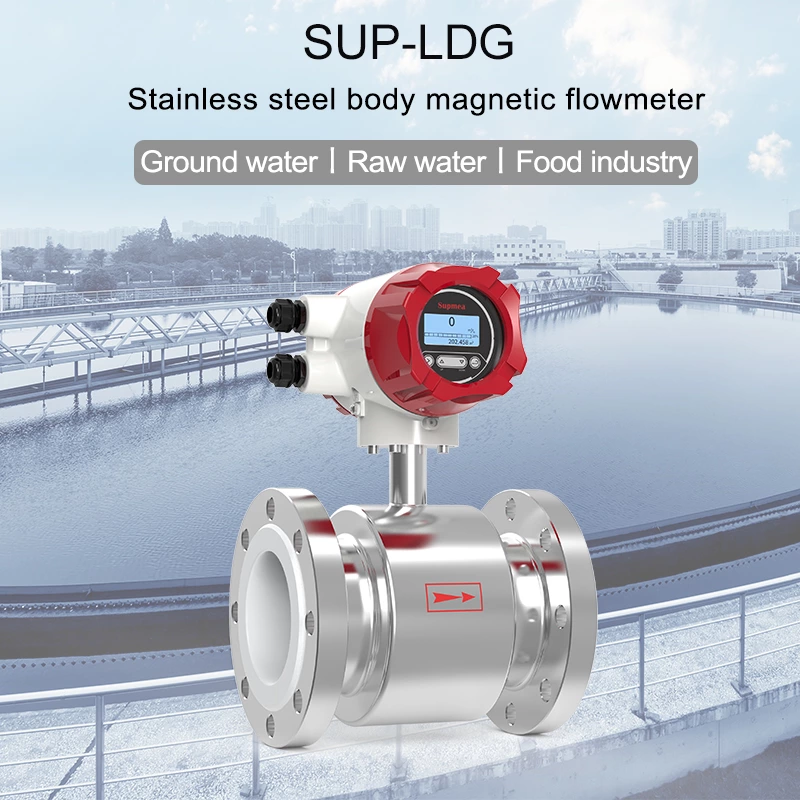

SUP-LDG Stainless steel body electromagnetic flowmeter

SUP-LDG Stainless steel body electromagnetic flowmeter

Share

Introduction

Magnetic flow meters operate under the principle of Faraday's Law of Electromagnetic Induction to measure liquid velocity. Following Faraday's Law, magnetic flowmeters measure the velocity of conductive liquids in pipes, such as water, acids, caustic, and slurries. In order of usage, magnetic flowmeter use in water/wastewater industry, chemical, food and beverage, power, pulp and paper, metals and mining, and pharmaceutical application.

Specification

Diameter Nominal

DN15(1/2”)~DN1000(40”)

Nominal Pressure

0.6~4.0 MPa (87~580 psi)

Accuracy

±0.5%,±2 mm/s flow rate <1 m/s (<3.28 ft/s)

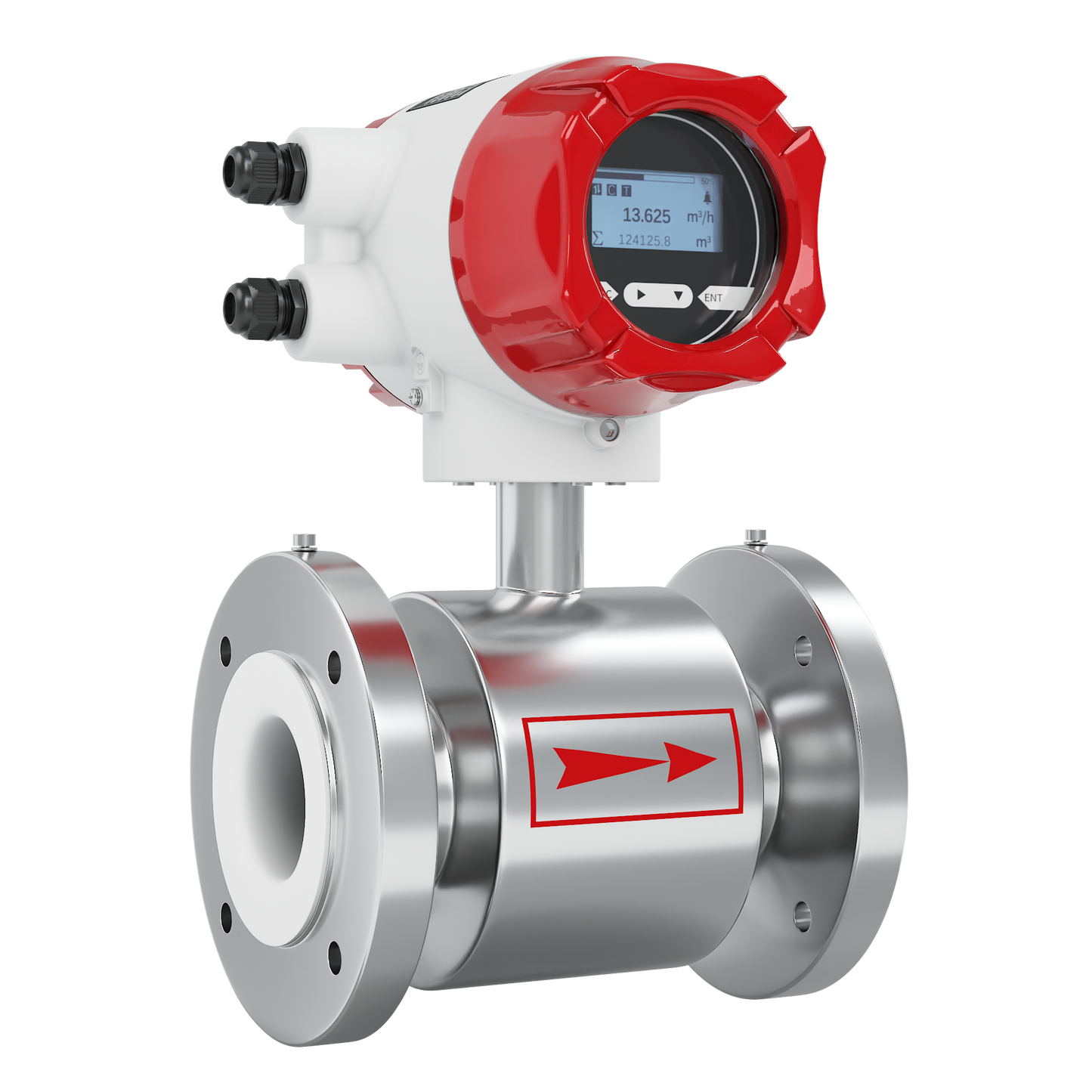

Liner Material

PFA, F46, Neoprene, PTFE, FEP

Electrode Material

Stainless steel SUS316L, Hastelloy C, Titanium, Tantalum, Platinum-iridium

Medium Temperature

- Integral type: -10℃~80℃ (14℉~176℉)

- Split type: -25℃~180℃ (-13℉~356℉)

Ambient Temperature

-10℃~60℃ (14℉~140℉)

Electrical Conductivity

- Water: 20 μS/cm

- Other medium: 5 μS/cm

Structure Type

Integral type, split type

Ingress Protection

IP65

Product Standard

JB/T 9248-1999 Electromagnetic Flowmeter

Features and advantages

Corrosion Resistance

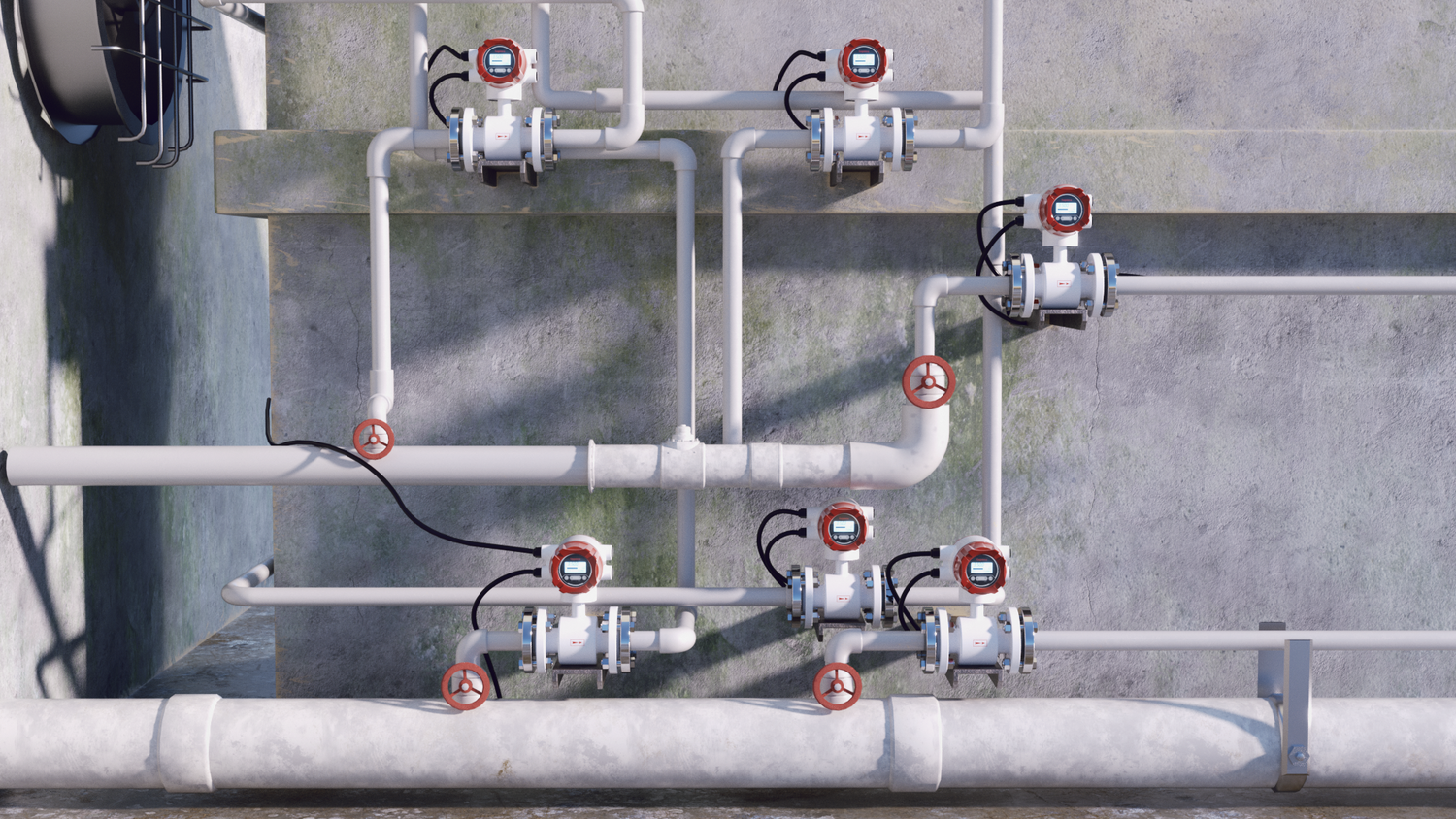

Stainless steel flow meters are highly resistant to corrosion, making them ideal for use in harsh environments, such as chemical processing plants, oil and gas refineries, and wastewater treatment facilities.

Accuracy

Stainless steel flow meters are known for their accuracy, providing reliable and consistent measurements of fluid flow.

Durability

Stainless steel is a robust material, which makes these flow meters durable and long-lasting, even under high pressure and temperature conditions.

Easy Maintenance

Stainless steel flow meters require minimal maintenance, which helps reduce downtime and operating costs.

Hygienic

Stainless steel is non-porous and easy to clean, making it a suitable material for use in the food and beverage industry, pharmaceutical industry, and other industries that require high levels of hygiene.

Wide Range of Applications

Stainless steel flow meters can be used to measure the flow of a wide range of liquids and gases, including water, chemicals, petroleum, and other fluids.

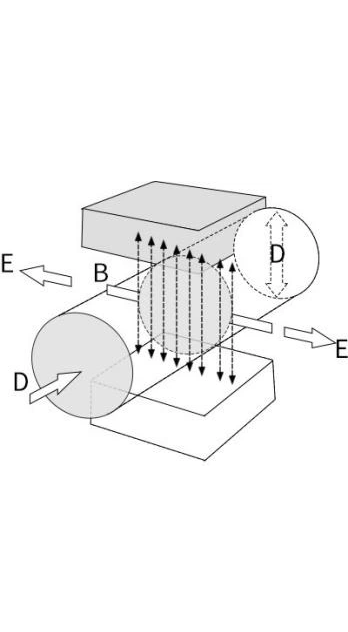

Measuring principle

Mag meter works based on Faraday's law, when the liquid goes through the pipe at the flow rate of v with a diameter D, within which a magnetic flux density of B is created by an exciting coil, the following electromotive E is generated in proportion to flow speed v:

E=K×B×V×D

Where:

E-Induced electromotive force

K-Meter constant

B-Magnetic induction density

V-Average flow speed in cross-section of measuring tube

D-Inner diameter of measuring tube